Product Details:

Mode |

LF-3015 STE |

LF-4020 STE |

LF-6015 STE |

LF-6025 STE |

|---|---|---|---|---|

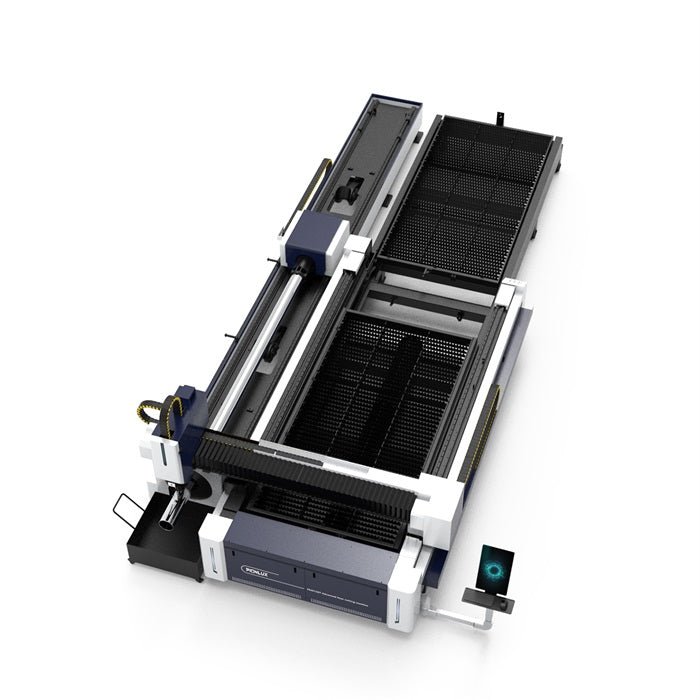

| Working Area | 3000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2500mm |

| XY Z Axis Stroke | 1520*3100*100mm | 2040*4050*100mm | 1520*6050*100mm | 2510*6100*260mm |

| Laser Power Supply | 2000w, 3000w, 6000w | |||

| Maximum Acceleration | 2G | |||

| Positioning Accuracy | ±0.03mm | |||

| Voltage | 380V 3PH 50/60HZ | |||

| Cutting Ability | Carbon Steel: 1-80mm, Stainless Steel: 1-70mm, Aluminum: 1-60mm, Brass: 1-20mm | |||

| Upgrade | Air Conditioner, Smoke Purifier, Air Compressor, Voltage Regulator | |||

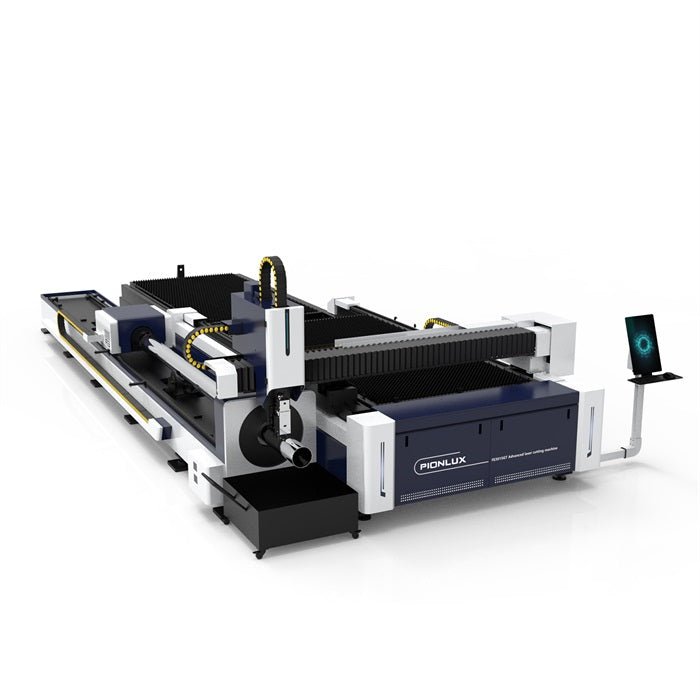

The Advantages of an Exchange Table in Laser Cutting Machines

- The LF-STE model builds upon the LF-ST model by adding an exchange platform,

saving time for loading and unloading during sheet cutting, reducing time

costs, and improving processing efficiency. - Fully intelligent CNC system with a user-friendly interface for easy operation. Low

maintenance requirements and simple upkeep, making it easy to use. - Highly integrated, with a long lifespan and energy-efficient design that

significantly reduces costs. It combines sheet and tube cutting capabilities,

processing various metal materials and pipe components.

In the ever-evolving landscape of manufacturing, laser cutting machines equipped with exchange tables have emerged as a significant innovation, particularly for industries dealing with metal sheets and tubes. An exchange table facilitates seamless loading and unloading of materials, effectively minimizing downtime during the cutting process. This elevated productivity translates into operational efficiency, allowing businesses to maximize output while maintaining high standards of precision.

One of the primary advantages of incorporating an exchange table in laser cutting machines is the ability to perform continuous operations. While one side of the table is utilized for cutting, the other side can be prepared with new materials. This concurrent process reduces idle time significantly, enabling manufacturers to achieve quicker turnaround times and meet tight production schedules. For instance, in the automotive industry, where precision and efficiency are paramount, the implementation of laser cutting machines with exchange tables has led to enhanced workflow, resulting in a notable increase in overall output.

Moreover, the capabilities of laser cutting machines to handle both metal sheets and tubes make them versatile tools for various applications. Industries such as aerospace, construction, and fabrication are leveraging these machines to cut complex designs with high accuracy. For instance, a fabrication shop specializing in custom metal components reported a 30% reduction in project lead times after switching to laser cutting machines equipped with exchange tables. The ability to quickly load and unload different materials not only improves workflow but also optimizes labor resources, ultimately leading to cost savings.

In summary, the integration of exchange tables in laser cutting machines provides numerous benefits, particularly in terms of productivity and efficiency. By minimizing downtime and allowing for flexible handling of materials, businesses can achieve higher output and improved cost effectiveness. This innovation has proved invaluable across various industries, showcasing the profound impact of adopting advanced manufacturing technologies.

Értékelések

Még nincsenek értékelések.