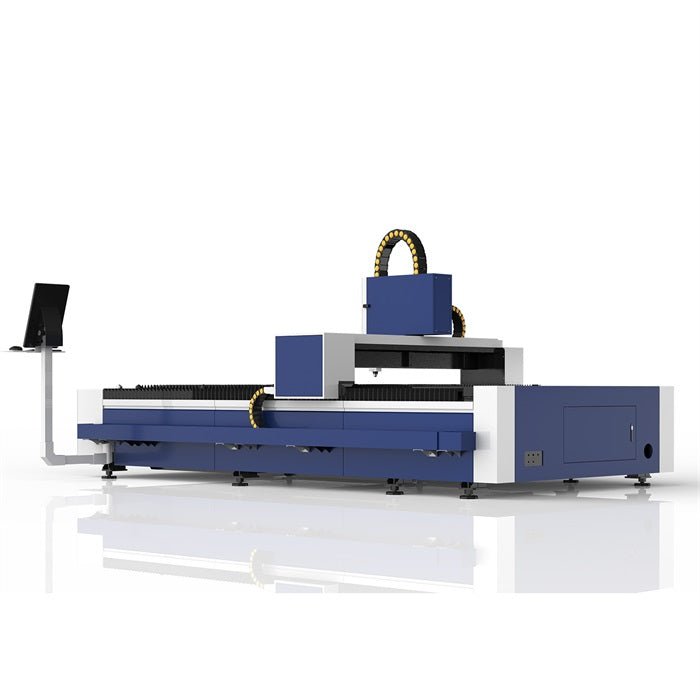

Product Details:

Mode |

LF-3015EA |

|---|---|

| Working Area | 3000*1500mm / 4000*2000mm / 6000*1500 / 6000*2500mm |

| X Y Z Axis Stroke | 1520*3100*100mm 1520*6050*100mm 2040*4050*100mm 2510*6100*260mm |

| Laser Power Supply | 1500w, 2000w |

| Maximum Acceleration | 0.8G |

| Positioning Accuracy | ±0.03mm |

| Voltage | 380V 3PH 50/60HZ |

| Cutting Ability | Carbon Steel: 0.8-16mm, Stainless Steel: 0.8-6mm |

| Upgrade | Independent Control Cabinet, Air Conditioner, Smoke Purifier, Air Compressor, Voltage Regulator |

What is a Fiber Laser Cutting Machine?

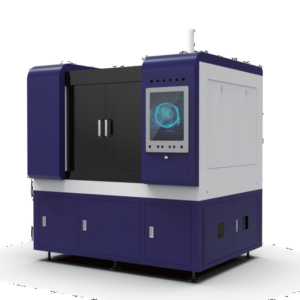

A fiber laser cutting machine is an advanced tool designed for the precise cutting of sheet metals through the utilization of fiber laser technology. Unlike traditional cutting methods, this machine employs a concentrated beam of light to achieve optimal precision and efficiency. The fundamental principle behind fiber laser cutting involves generating a high-intensity beam using a fiber optic cable, which converts electrical energy into light. This light is then focused into a small, intense point capable of melting, burning, or vaporizing various types of metal materials.

The key components of a fiber laser cutting machine include the laser source, optics, and cutting head. The laser source is the heart of the machine, producing the fiber laser necessary for cutting. The optics are responsible for directing and focusing the laser beam onto the workpiece, while the cutting head holds various nozzles that aid in the cutting process. Together, these components work in unison to deliver precise and intricate cuts on a range of materials, including stainless steel, aluminum, brass, and carbon steel.

One notable advantage of fiber lasers over conventional CO2 lasers is their efficiency in cutting reflective metals such as copper and brass, which can be challenging for CO2 lasers. Fiber laser machines offer a higher cutting speed, reduced maintenance requirements, and lower energy consumption, resulting in a cost-effective solution for various industries. Moreover, the smaller size of the fiber laser cutting system allows for more compact workstation setups, enhancing workflow efficiency. Overall, fiber laser cutting machines stand out as a reliable choice for manufacturers seeking advanced technology for metal fabrication.

Benefits of Using Fiber Laser Cutting Machines for Sheet Metals

Fiber laser cutting machines are rapidly gaining popularity in the realm of sheet metal processing due to their numerous advantages over conventional cutting methods. One of the most noteworthy benefits is the increased cutting speed these machines offer. Fiber lasers can achieve cutting speeds significantly higher than traditional methods, enabling manufacturers to enhance their throughput and meet production deadlines more efficiently. This characteristic is particularly beneficial in high-volume manufacturing scenarios where time is a critical factor.

Improved precision is another major advantage of fiber laser technology. These machines provide exceptional accuracy and repeatability, which are crucial for producing intricate designs and components with tight tolerances. The focused laser beam ensures minimal heat-affected zones, reducing the risk of warping or distortion during the cutting process. Consequently, businesses can achieve high-quality results with minimal need for secondary operations, streamlining their production workflows.

Lower operational costs represent an essential benefit associated with fiber laser cutting machines. These systems typically consume less power compared to other cutting technologies, such as plasma or waterjet cutters. Additionally, the longevity and durability of fiber lasers reduce maintenance requirements, resulting in fewer interruptions and lower overall maintenance expenses. This energy efficiency not only contributes to decreased operational costs but also promotes environmentally friendly manufacturing practices.

Furthermore, fiber laser cutting machines exhibit remarkable versatility, capable of cutting a wide range of metal thicknesses and types, including stainless steel, aluminum, and copper. This adaptability allows manufacturers to cater to diverse market demands and navigate fluctuating material requirements more adeptly. Real-world applications, including automotive, aerospace, and metal fabrication industries, showcase successful implementations of fiber laser cutting technology. Companies leveraging this cutting-edge machinery have reported substantial enhancements in productivity, ultimately reinforcing its value as a transformative tool for modern manufacturing operations.

Értékelések

Még nincsenek értékelések.