Product Details:

-

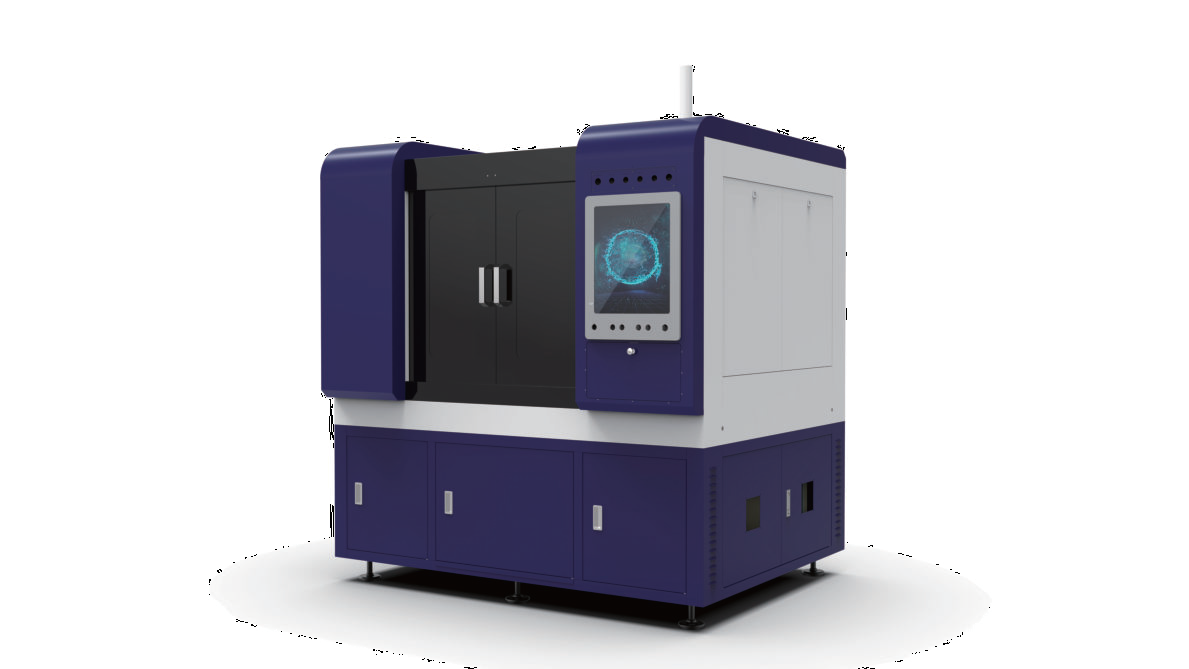

ModeLF-6060MiWorking Area

600*600mm X Y Z Axis Stroke600*600*100mmLaser Power Supply1000w, 1500w, 2000w, 3000w, 6000w,Footprint1480*1480*2050mmMaximum Acceleration1.5GPositioning Accuracy±8μmVoltage380V 3PH 50/60HZUpgradeAir Conditioner, Smoke Purifier, Air Compressor, Voltage Regulator

Understanding High Precision Laser Cutting Technology

High precision laser cutting technology has revolutionized the fabrication and machining industries by enabling intricate designs and shapes to be cut from various materials with remarkable accuracy. At the heart of this technology is the laser source, which generates a highly concentrated beam of light. This beam can be fine-tuned to achieve specific parameters, allowing for deep penetration and clean cuts in thin sheets, making it an ideal solution for applications that demand precision.

The guidance system is another critical component that influences the accuracy of the cutting process. Modern laser cutting machines utilize advanced sensors and software algorithms that ensure the laser beam follows the desired path without deviation. This system must operate within microscopic tolerances to maintain the required precision, especially in industries such as aerospace, automotive, and electronics where even the slightest error can lead to significant consequences.

Furthermore, the cutting head is designed to control the positioning and focus of the laser beam as it moves across the material. This component is engineered for optimal performance, incorporating features such as adjustable focal lengths that adapt to varying material types and thicknesses. The evolution of these components over time has resulted in more sophisticated methodologies that prioritize stability and precision during high-speed operations, thereby reducing the likelihood of material deformation or waste.

High precision laser cutting technology also plays a vital role in manufacturing and prototyping, as it allows for rapid creation of components that can lead to improved product quality. This precision not only enhances the aesthetic appeal of the final product but also minimizes material waste, as the cutting process generates significantly less scrap compared to traditional methods. As industries continue to embrace laser cutting technology, the demand for high precision solutions will only grow stronger, shaping the future of production and innovation.

Benefits of High-Speed Laser Cutting for Thin Sheets

High-speed laser cutting technology has revolutionized the processing of thin sheet materials, offering numerous advantages that enhance manufacturing efficiency and productivity. One of the most notable benefits is the efficiency of the cutting process. High-speed laser cutting machines significantly reduce production time by allowing manufacturers to execute cuts with remarkable speed and precision. This efficiency leads to improved throughput, meaning that businesses can achieve higher output levels within shorter time frames, ultimately leading to increased profitability.

Moreover, the compact design of high-speed laser cutting machines is particularly advantageous for manufacturers confronted with space constraints. The small footprint of these machines permits their integration into various manufacturing environments without requiring extensive alterations to existing setups. This is increasingly beneficial for smaller businesses aiming to optimize their operations while maintaining a dedicated space for laser cutting processes.

Another crucial aspect to consider is the operational cost reduction associated with high-speed laser cutting. By enhancing cutting speed while maintaining great accuracy, manufacturers can minimize material waste, resulting in lower consumption of raw materials. This operational efficiency extends to energy consumption as well; high-speed machines often require less power per unit processed compared to traditional cutting methods, further reducing overall costs.

Industry case studies exhibit the successful implementation of high-speed laser cutting technology across diverse sectors such as automotive, aerospace, and electronics. Companies within these industries have reported significant improvements in production efficiency, with precise, clean cuts allowing for seamless assembly and reduced rework. The advantages of high-speed laser cutting for thin sheets thus culminate in a transformative impact on both productivity and cost-effectiveness, positioning it as a critical tool in modern manufacturing processes.

Értékelések

Még nincsenek értékelések.