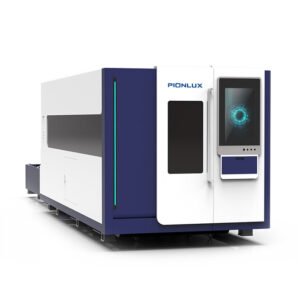

Product Details:

-

Mode LF-3015PE LF-6015PE LF-4020PE LF-6025PE LF-12025PE Working Area 3000*1500mm 6000*1500mm 4000*2000mm 6000*2500mm 12000*2500mm X Y Z Axis Stroke 1520*3100*100mm 1520*6050*100mm 2040*4050*100mm 2510*6100*260mm 2510*12500*260mm Laser Power Supply 2000w, 3000w, 6000w, 12000w, 20000w, 30000w, 40000w, 50000w, etc. Maximum Acceleration 2G Positioning Accuracy ±0.03mm Voltage 380V 3PH 50/60HZ Cutting Ability Carbon Steel: 1-80mm, Stainless Steel: 1-70mm, Aluminum: 1-60mm, Brass: 1-20mm Upgrade Air Conditioner, Smoke Purifier, Air Compressor, Voltage Regulator, Safety Light Curtain, Door Protection Switch

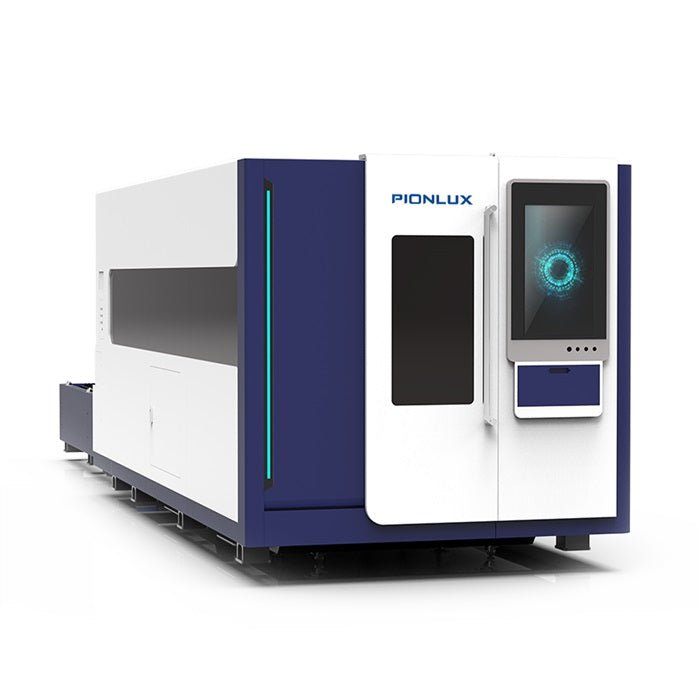

Machine properties:

- The high-strength metal protective case shields the operator from laser

radiation, while also providing an enclosed and environmentally friendly

solution for collecting and disposing of fumes and debris. - The 3015-sized exchange table can complete exchanges in as fast as 10 seconds,

saving loading and unloading time and enhancing machine efficiency.

Additionally, the large-size operation screen caters to various customer

needs. - Two surveillance cameras enable the operator to monitor the cutting head’s

operation without opening the door, and detect the loading and unloading of the

rear bed without any movement.

High-Strength Metal Protective Case: Ensuring Operator Safety

The implementation of a high-strength metal protective case in fiber laser cutting machines is paramount for ensuring operator safety. These cases serve as a critical barrier, effectively shielding operators from harmful laser radiation that can lead to severe injuries or long-term health risks. In an industrial environment where safety standards are increasingly prioritized, the protective casing becomes not only a feature but a necessity. The integration of advanced materials in the construction of these cases enhances their ability to withstand extreme conditions while providing optimal protection.

The materials typically used in the fabrication of these protective cases include high-density metals such as steel and aluminum, which offer excellent durability and resistance to wear. This choice of materials not only enhances the structural integrity of the protective case but also contributes to the overall lifespan of the fiber laser cutting machine. The robust construction ensures that the casing can endure the rigors of daily operations, thereby minimizing the risk of accidental exposure to the laser beam.

Adhering to stringent safety standards and regulations, these high-strength metal protective cases are designed to comply with industry safety protocols. This compliance proves essential in creating a safe workplace environment, aligning with the overarching goal of reducing workplace hazards. By investing in fiber laser cutting machines equipped with such protective features, businesses demonstrate their commitment to safeguarding their personnel. The combination of enhanced operator safety, durability of materials, and adherence to safety regulations underscores the fundamental importance of a well-designed protective casing in modern metal fabrication operations.

Enclosed Solution for Fume and Debris Management

The implementation of enclosed solutions in fiber laser cutting machines significantly enhances fume and debris management. These machines feature a well-engineered design that facilitates the effective capture and disposal of harmful emissions and particles generated during the cutting process. By integrating advanced ventilation systems and specialized filters, enclosed fiber laser cutting machines can minimize the release of harmful substances into the work environment. This not only contributes to a safer workplace but also aligns with environmental regulations aimed at reducing industrial emissions.

One of the key advantages of an enclosed design is its ability to contain smoke and debris within a designated area, which prevents the spread of pollutants into the surrounding environment. The filtration systems employed in these machines are typically equipped with HEPA or activated carbon filters that actively remove particulates, fumes, and noxious gases, thereby ensuring cleaner air quality. In doing so, these systems not only protect the environment but also safeguard the health of operators who may be exposed to harmful emissions during the cutting process.

Moreover, minimizing the release of fumes and debris translates into reduced cleanup times and increased operational efficiency. With an enclosed solution, workers spend less time managing waste and cleaning workspaces, allowing them to focus more on production and other critical tasks. This streamlined workflow can lead to overall improvements in productivity, as machines equipped with these safety features run more efficiently and require less maintenance due to reduced contamination risks.

In summary, utilizing enclosed fiber laser cutting machines with robust fume and debris management systems contributes to a healthier work environment and a more sustainable operational framework, benefiting both workers and the planet.

Értékelések

Még nincsenek értékelések.