Product Details:

-

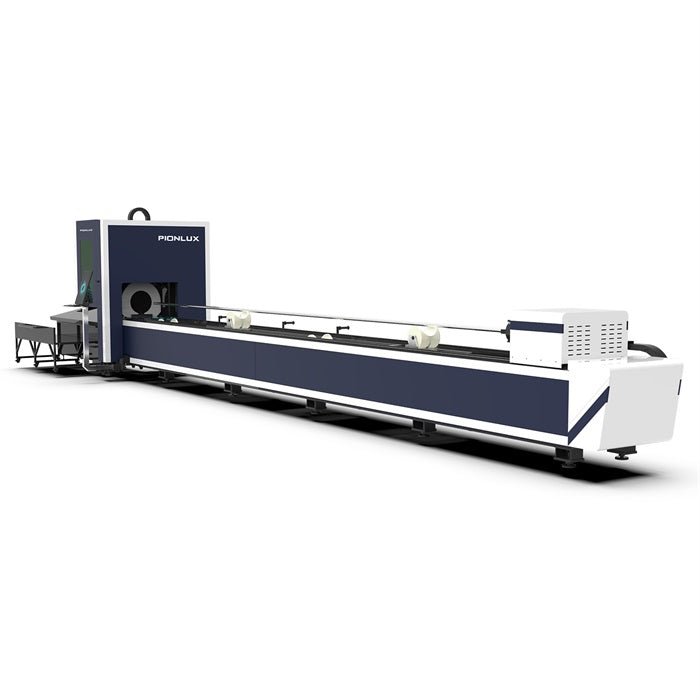

Mode LF-6024T LF-6035T Min Diameter Φ20mm □20mm Φ20mm □20mm Max Diameter Φ240mm □240mm Φ350mm □350mm Laser Power Supply 1500w, 2000w, 3000w, 6000w Maximum Acceleration 1.5G Positioning Accuracy ±0.03mm Voltage 380V 3PH50/60HZ Chuck Speed 60r/min Upgrade Alr Conditioner, Smoke Puriher, Air Compressor, Voltage Reglator, Satety Lignt Curtain

Understanding Fiber Laser Technology

Fiber laser technology represents a significant advancement in the field of laser cutting, especially for pipes and tubes. The principle behind fiber lasers involves the use of a solid-state medium—a glass fiber doped with rare earth elements, typically ytterbium. This design leads to improved efficiency and effectiveness compared to traditional laser sources, such as CO2 lasers. The light produced by the fiber laser is generated within the fiber itself, allowing for a compact and robust system capable of producing highly concentrated beams at various wavelengths.

The benefits of fiber laser technology in tube and pipe cutting are manifold. First and foremost, fiber lasers are known for their exceptional cutting speeds and precision, which translate to increased productivity in industrial applications. The focused laser beam allows for clean cuts, with minimal thermal distortion, reducing the need for extensive post-processing. This is particularly advantageous when dealing with metals, such as steel, aluminum, and titanium, which are widely used in industrial sectors.

Another significant advantage is the ability to cut intricate shapes and designs with high repeatability and accuracy. Unlike traditional cutting methods, which may require elaborate setups and adjustments, fiber lasers can adjust to various material thicknesses and types with remarkable adaptability. This flexibility is essential for industries where customization and rapid prototyping are vital, enabling manufacturers to meet specific client requirements effectively.

Recent advancements in fiber laser technology have further enhanced its capabilities. Innovations such as multi-kilowatt fiber lasers and adaptive cutting techniques have surged cutting speeds while maintaining pinpoint precision. The integration of automated systems with fiber lasers also facilitates improved workflow management, making them an optimal choice for modern manufacturing environments. Thus, the adoption of fiber laser cutting machines significantly elevates the standards of operational efficiency and product quality in the pipe and tube cutting industry.

Benefits and Applications of Fiber Laser Tube Cutting Machines

Fiber laser tube cutting machines have emerged as a transformative technology in various industries, offering a plethora of benefits that enhance production efficiency. One of the most significant advantages is their high cutting speed. These machines can achieve rapid processing times, enabling manufacturers to meet increasing production demands without sacrificing quality. The remarkable speed, coupled with their ability to operate continuously, significantly boosts overall productivity.

In addition to speed, exceptional accuracy is a hallmark of fiber laser technology. These machines utilize advanced optical systems to deliver precise cuts, minimizing the margin of error and ensuring that the end products consistently meet stringent specifications. This level of accuracy is particularly beneficial in industries such as aerospace and automotive, where tolerances are critical, and any deviation can lead to costly rework or failure of components.

Another noteworthy benefit is the reduced material waste associated with fiber laser tube cutting. The focused laser beam ensures that cuts are extremely clean, which translates into less scrap material. This efficiency not only lowers raw material costs but also promotes environmental sustainability—an increasingly important consideration in modern manufacturing practices.

Operational costs are further minimized due to the long lifespan and low maintenance requirements of fiber laser machines. With fewer moving parts compared to traditional cutting technologies, these machines experience less wear and tear, resulting in lower maintenance expenses.

Industries such as manufacturing, automotive, and aerospace utilize fiber laser tube cutting machines extensively for applications including the production of exhaust systems, structural components, and intricate tube configurations. As demand for customization and rapid prototyping rises, fiber laser machines are expected to evolve, incorporating advanced features such as automation and smart technology to streamline operations. As these industries continue to embrace innovation, fiber laser tube cutting machines will play a pivotal role in driving efficiency and facilitating future growth.

Értékelések

Még nincsenek értékelések.